With over 20 years of experience from a variety of operations and locations around the world, X-Act Wells have accumulated knowledge, competency and best practices that is available to our customers. Some specialty tags are listed below. Click the links for more details.

Deep water operations

Is there more to "deep water operations" other than it takes longer to run the wear bushing? Absolutely. This is not to say that it is more difficult than other well operations, but there are special challenges that must be considered both in the planning and execution phase. Soft seabed, shallow water flow, narrow margins, hydrates, thermal effects in long riser, tight clearance well designs and much more.

Logistics is another consideration: large conductors and surface casing, mud-hungry drilling procedures (or riserless mud recovery) and, for dual-derrick rigs: the shear amount of planning and vessels required to "feed the beast" as one string is being run with drilling operations take place simultaneously.

X-Act Wells have planned and drilled deep water wells since 2006 in many different parts of the world, each with its unique set of risks:

- West of Shetlands with harsh weather and reactive shallow formations

- Asia-Pacific's complex shallow hazards settings

- Operating offshore French Guiana in 4 knots surface current, extreme pore pressure ramps and low ROP through hard formations

- Massive salt sections / exit procedures and managing ballooning in the Gulf of Mexico

- Narrow margin drilling and OBM-cuttings management in the Norwegian Continental Shelf.

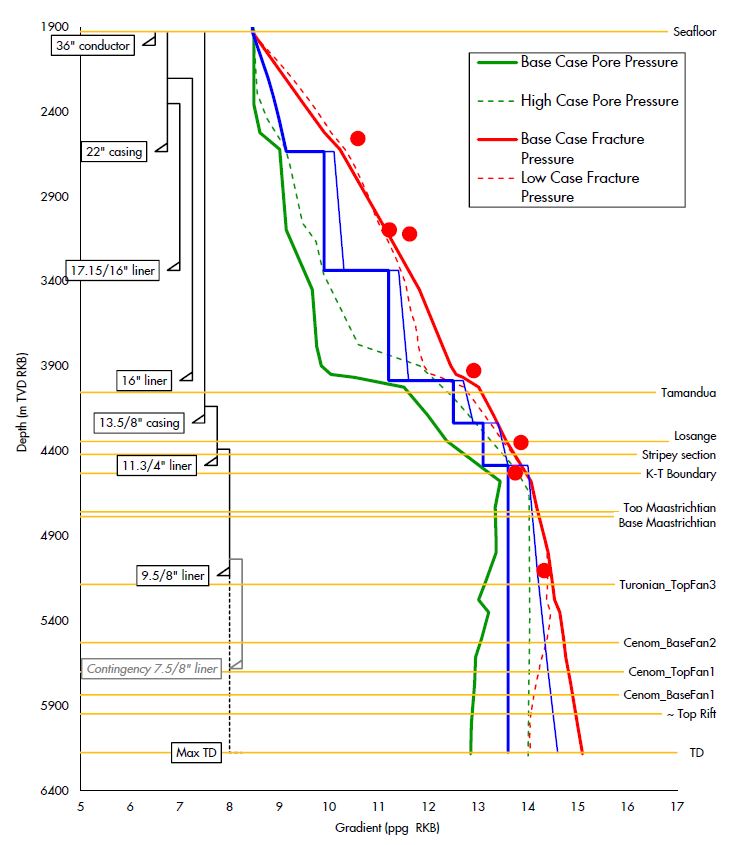

Narrow Margin Drilling

In wells with small window between pore pressure and formation strength: every meter counts. It's about maximizing the drilled intervals and pushing sections so close to the pressure ramps that the drill bit gets nervous. Some of the keys to success is a flat-rheology mud system in perfect condition and strict use of PWD to manage ECD - juggling around with margins of 0,03 ppg or less. If the downhole pressure exceeds the formation strength, losses may occur. If the mud weight is approaching pore pressure or the wellbore stability line, hole problems or an influx can appear on connections when the ECD is turned off.

Let the formation "talk" and listen to it by making observations and act accordingly on even the smallest sign of trouble. Establish consistency in connection practices and fingerprinting. Keep close control of the bottoms-up time and look for indications of gas from previous pumps-off event when ECD was removed. If a sand is penetrated, it might even be an idea to spend some time to simulate a connection and pump bottoms up to see what the effect was. Use of Controlled Mud Level technology to lower the mud column in the riser provides an unprecedented control of the bottom hole pressure under dynamic conditions.

These are some of the methods than can be applied to create the space needed reach the desired depth and skip that annoying contingency liner that would have cause lots of add-on issues to deal with.

Riser analysis

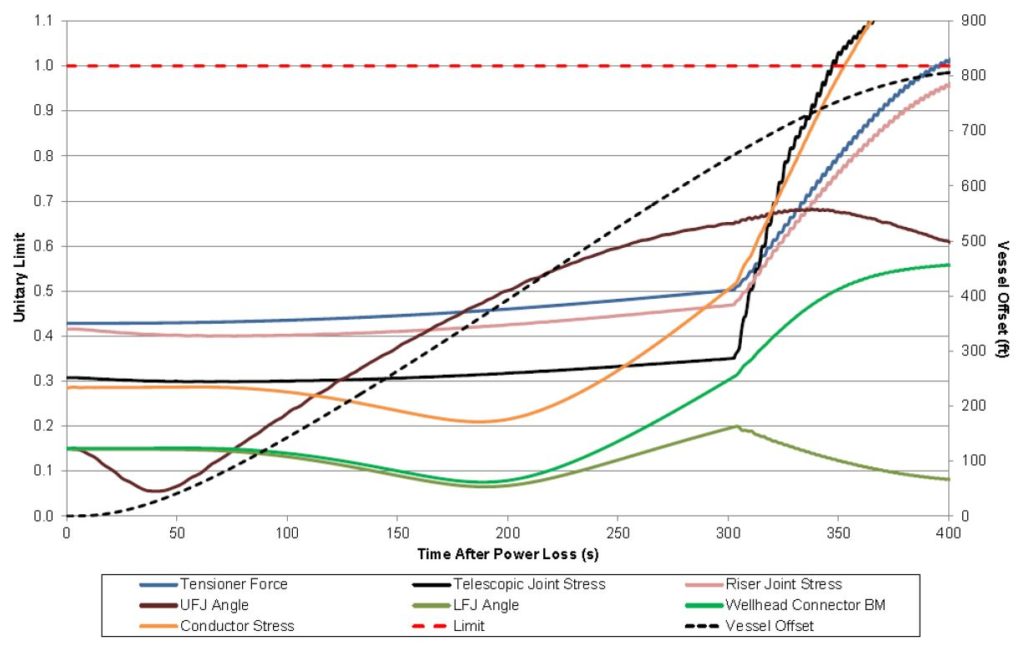

The larger the water depth, the more attention should be brought to the riser analysis. Such assessments should also include the conductor and surface casing to check structural capacity and fatigue loads.

So what's the big deal? Well the obvious one is the weight. 3000 meters of riser is a lot of steel, so it is crucial to figure out the configuration of buoyed joints in order to establish a comfortable top tension range that the system can cope with for all conditions and mud weights in use.

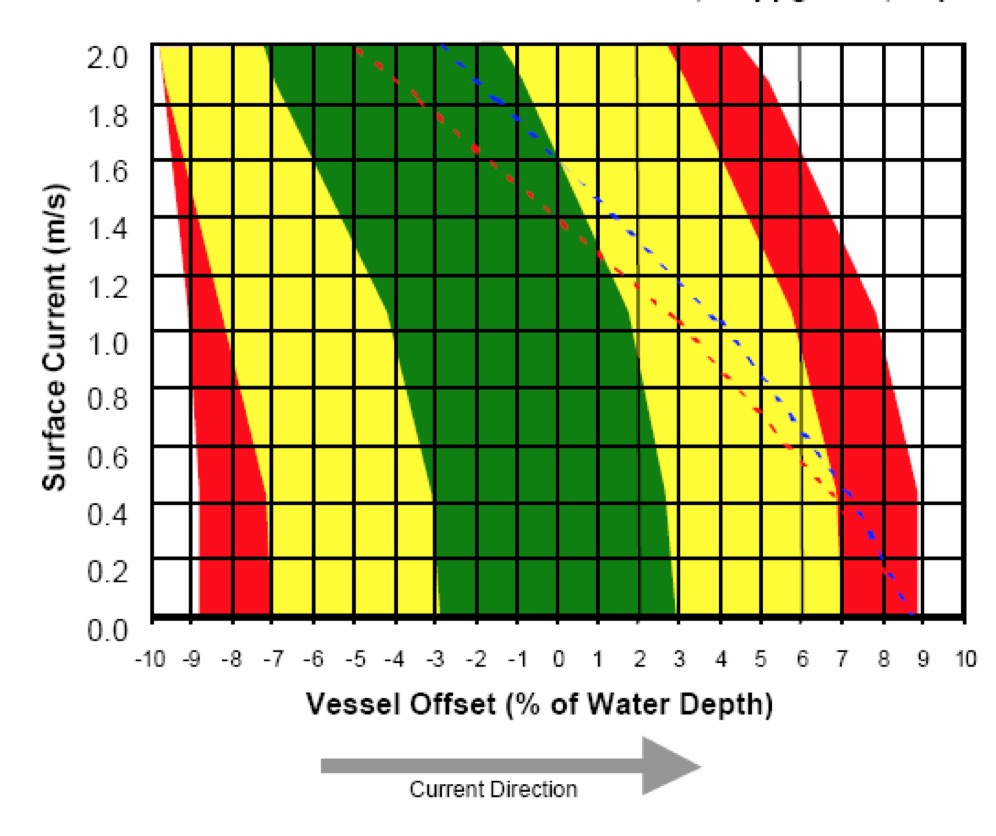

Then there is API16Q which lays out the boundaries and limits for the riser system, both in terms of flex joint angels and von miese stresses in Drilling, Suspended and Survival modes. The drift-off simulations coupled with weak-point analysis will give the most important inputs into the Well Specific Operating Guideline and watch circles of the DP rig. This is also coupled with the Well Control Plan for the project to establish which EDS modes to use on the BOP control system. Small watch circles can be increased by accepting a EDS mode with less functions, provided the risks and acceptable and managed ALARP.

Last, but not least: Vortex Induced Vibrations in the riser system caused by currents in the sea column is definitely a situation to avoid. These cyclic lateral movements can take out huge chunks of the fatigue life from your structural design. Fairings can be used to break the eddy-currents and minimize the VIV effect.

Dynamic position management / WSOG

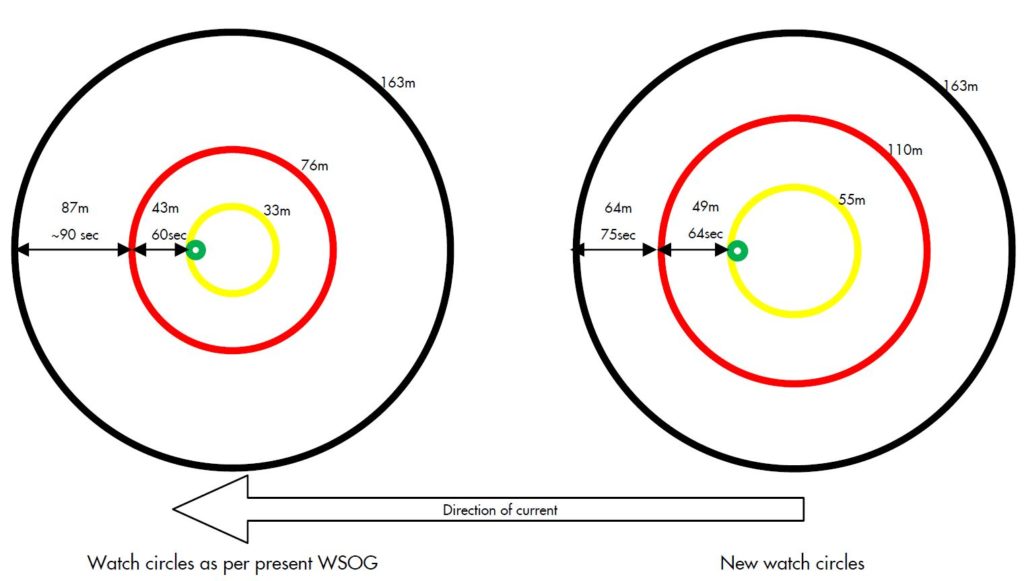

The watch circles and many other considerations that affect DP operations, power allocation /priority, weather conditions and other marine risk elements are captured into a document called the Well Specific Operating Guideline (WSOG).

Once the riser analysis and drift-off curves are established the DP watch circles can be set, starting from the outer circle called the Point of Disconnect (POD). If the rig / drillship is still attached to the well at this offset or beyond, something will yield or break. It is important that the duration of the disconnect sequence is known so that, combined with the drift-off curves, the Red watch circle can be established. If the rig encounters DP problems and reaches the Red watch circle the Emergency Disconnect Sequence must be initiated to ensure there is sufficient time to secure the well and unlatch the LMRP prior to reaching the POD.

The Yellow watch circle can vary depending on operations. Watch circles are generally larger with increasing water depth, but environmental and metocean conditions can result in fast drift-off speeds and associated small watch circles. In certain areas dynamic watch circles should be derived to maximize operability of the vessel. If the data used for the drift-off modelling is too conservative (example: 1 year current and wind, co-linear with waves hitting the unit at the worst heading) this can lead to frequent suspension of operations as the Yellow watch circle is breached. For example: when operating in areas with high currents the riser may take a shape that results in upper flex joint angle approaching or exceeding the drilling limits even with the rig positioned directly above well location. In these circumstances, the use of dynamic watch circles in combination with offsetting the set-point (subject to risk assessment and additional mitigation).

Operability assessments

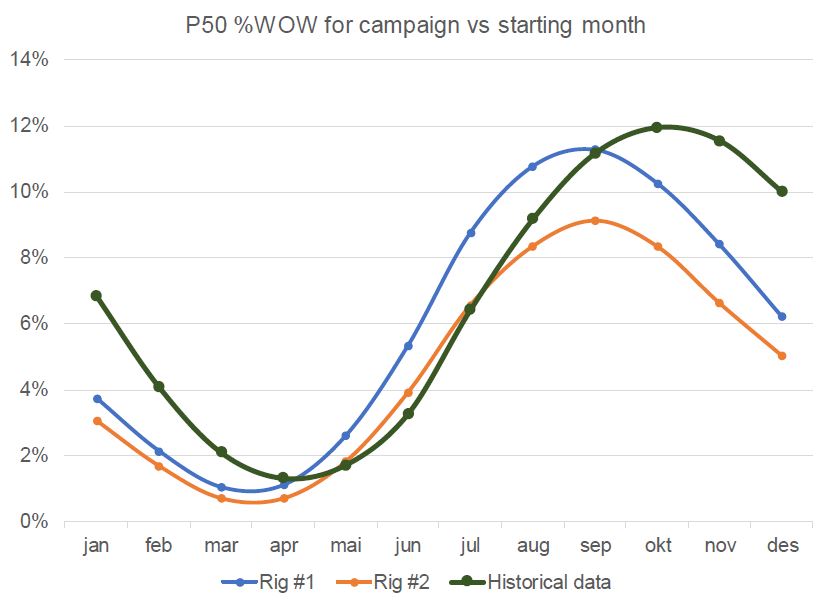

How much time Waiting on Weather (WOW) should be included in the time estimates? That depends on a number of things:

- What kind of weather and metocean conditions exist at the location?

- What time of year will the operations take place?

- What is the duration of the program?

- How does the rig behave in weather (using RAO curves) and what are the limitations of the equipment on board?

- What other non-rig limitations must be considered (example: supply vessels)

An accurate WOW estimate is not only important for budgeting purposes (P10, P50, P90 WOW impact) but these assessments can also be very useful in the rig tender evaluation phase in order to quantify and compare the WOW impact for the different rigs offered in the tender.

The WOW assessment will also highlight lmitations and weather sensitive operations and/or equipment capabilities. This can help the team prioritise efforts to minimize WOW impact either through modification of equipment or procedureal changes.

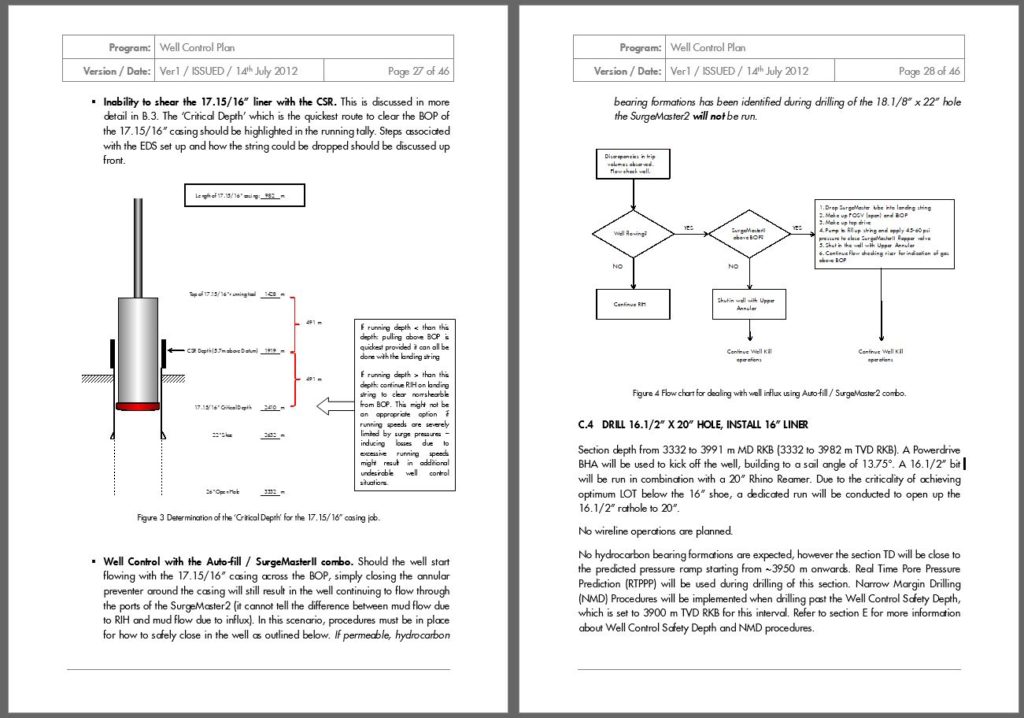

Well control procedures

Most companies have pressure control manuals, procedures and / or well control training requirements. However, there are many situations that go beyond the syllabus of IWCF or other mandatory well control training programs. In fact; like each well has its own drilling program, each well should have a dedicated well control plan that captures the specific risks and mitigations for maintaining barriers in the well.

For example: in some sections, the Drillers Method may not be the best method for circulating out a kick. In other sections riser margin may only be present down to a certain depth, which may affect the procedures related to temporary suspension. Which tubulars are shearable with the BSR and / or the CSR? How are the DP watch circles affected by changing to a different EDS mode for non-shearables? What are the contingency tasks for the ROV if the auto-shear is temporarily disarmed? These are some examples of useful information that should be captured in a well control plan.

Bridging documents & Contingency plans

Operators, rig contractors and service providers all have different management systems. When joining forces on a project it is important to identify where (if at all) there may be conflicts between the management systems and agree how to handle these conflicts. This process starts with a gap analysis to summarize all conflicts and deviations. Once the agreed procedures have been agreed, the final plan is captured in a bridging document that is normally signed off by all parties. The most common topics where bridging documents are required in well operations are:

- HSE Management System

- Emergency Response

- Well Control procedures

Before starting any project it is also important to do a thorough assessment of the risks and look at the barriers on the right-hand side of the bow tie. This is where contingency plans are required. How is the operating unit set-up to handle a major spill, significant well control event or other major hazard events like blow-out multiple fatalities? Can the well be capped, and is there a capping stack available? Is it possible to mobilize the contingency equipment whilst meeting all internal and regulatory requirements? This, and much more, are covered in well control contingency plans.

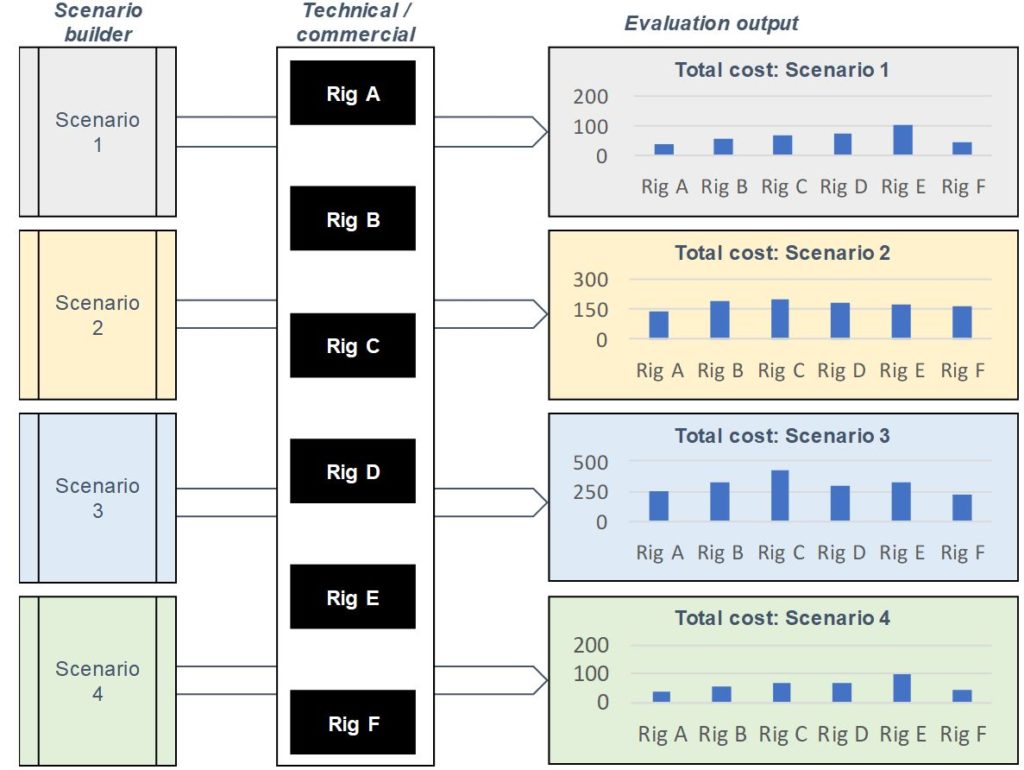

Rig tender & Contracting

How to select the rig that is most efficient for your campaign? There is much more to it than simply the day rate:

- Dual-derrick and offline capabilities

- KPIs (tripping speed, running riser / BOP, etc)

- Rig status (warm, cold, new-build)

- Crew composition and experience level

- Operability in harsh weather, %WOW

- Services included in rate?

- HSE trend and statistics

- Upgrades or modifications required?

- Suitability with specific scope (well test, deep water operations, etc)

By using a comprehensive evaluation model all of the above parameters, and more, are normalized and quantified to enable like-for-like comparison between the different rigs. The model will be tailor made to match the value drivers for your campaign, and can also be run for different scenarios, for example optional wells or success-case scope.

The specific information needed for the evaluation is requested in the tender to ensure the model can be set up as efficiently as possible without spending excessive time going through large amounts of documentation received. The added benefit of this kind of targeted tender evaluation is the rig contractors don't have to spend time compiling and submitting documentation and information that is not relevant for the evaluation phase.

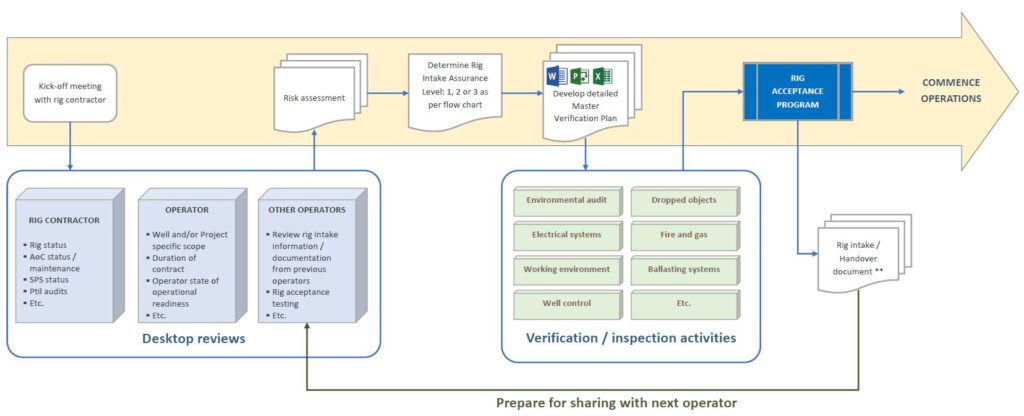

Rig intake, acceptance and start-up

The rig intake process can be demanding for both the operator and rig contractor. It is an important process to ensure rig is compliant with regulations whilst satisfying the technical requirements for the planned operations. Using a risk-based approach, the rig intake scope can be scaled. For example, if the operator has previous experience with the rig it is not necessary to repeat inspection and verification activities from previous rig intake. Also, if the previous operator has shared rig intake documentation and information, then some scope may be reduced to simple spot-checks and verification activities.

In the "Rig intake framework" document from April 2021 (Shell, WintershallDEA, DNO, Lundin, Neptune and Total) a proposed process for scaling and establishing rig intake scope is described. Collaboration and sharing with other operators is encouraged to avoid duplication of work and and keep track of deviations / open action items over time.